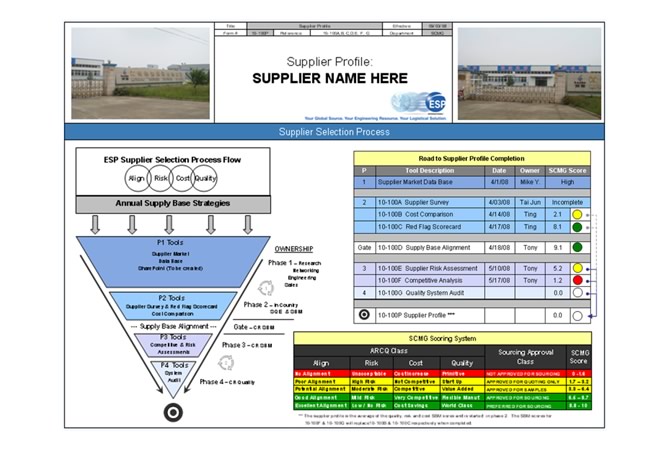

Finding a new supplier in emerging markets is a delicate balance between cost, quality, and risk. ESP has developed a supplier selection process called ARCQ that consists of a series of tools to “Align” your needs for “Risk”, “Cost” & “Quality”.

Global Supplier Qualification

The Global Supply Quality Engineers (SQEs) at ESP China and ESP India work with our supply base partners in Asia and India to assure quality product in from their factories. The SQEs also audit and monitor quality systems with our suppliers. ESP leverages our current supply base in the U.S., Mexico, India, China & Taiwan and are currently set up to support all of your Asian Operations with our products & services.

Manufacturing Process Review

ESP SQE’s are on site from the beginning of a project through the delivery process checking all the critical stages of new part processing. Validating tool and fixture design is critical to assure the integrity of the finished part from run to run. New parts go through a design review that incorporates an assessment of the tooling, fixture design to meet essential datum points, process verification and Cpk analysis, and final inspection. All data is captured and presented to our customer for approval prior to production and subsequent production runs.